Low Noise High Efficiency Three-Phase Asynchronous Motor Beautiful appearance, high efficiency and energy saving, low noise, small vibration, reliable operation. Widely used in various fields of national economy, such as machine tools, water pumps, fans, compressors, and also suitable for transportation, mixing, printing, agricultural machinery, food and other occasions without flammable, explosive or corrosive gases.

YE3 Low Noise High Efficiency Three-Phase Asynchronous Motor

-

Description

1. Corrosion Resistance:

The primary advantage of PP-R materials is their inherent resistance to corrosion. Unlike traditional metal pipes, PP-R pipes do not corrode, rust, or scale over time. This resistance to corrosion significantly extends the life of the plumbing system and reduces maintenance costs.2. Chemical Resistance:

PP-R Conversion Joints are highly resistant to chemicals, making them suitable for use in environments where chemical exposure is a concern. This resistance also means that the joints will not degrade or become compromised when exposed to common cleaning agents or other chemicals.3. High Temperature and Pressure Resistance:

These joints are designed to withstand high temperatures and pressures, which is crucial in systems that require hot water or high-pressure applications. The material's ability to maintain its structural integrity under these conditions ensures the safety and reliability of the plumbing system.4. Leak-Proof Connections:

The PP-R Conversion Joints are designed with a leak-proof connection system. The use of heat fusion or push-fit technology ensures a secure, tight seal that prevents leaks and maintains the integrity of the plumbing system.5. Flexibility and Durability:

PP-R pipes are known for their flexibility, which allows them to bend without breaking. This flexibility reduces the risk of damage from ground movement or other external forces. Additionally, the material's durability means that it can withstand the wear and tear of daily use without cracking or breaking.6. Lightweight and Easy to Install:

PP-R Conversion Joints are lightweight, making them easier to handle and install compared to traditional metal pipes. This ease of installation can lead to reduced labor costs and faster project completion times.7. Scalability and Adaptability:

These joints are designed to be adaptable to various plumbing systems, allowing for easy integration with existing infrastructure. This adaptability makes them a versatile solution for a wide range of applications, from small residential projects to large commercial installations.8. Energy Efficiency:

The insulating properties of PP-R materials help to reduce heat loss in hot water systems, thus energy savings and a smaller environmental footprint.9. Health and Safety:

PP-R pipes are non-toxic and do not leach harmful chemicals into the water, ensuring that the water supply remains safe for consumption. This is particularly important in healthcare facilities and other environments where water quality is a critical concern.10. Cost-Effectiveness:

While the initial cost of PP-R Conversion Joints may be higher than some traditional materials, their long-term cost savings due to reduced maintenance, durability, and energy efficiency make them a cost-effective choice over time.In conclusion, Corrosion Resistance PP-R Conversion Joints offer a range of benefits that make them an attractive option for any plumbing project. Their corrosion resistance, chemical resistance, durability, and adaptability, combined with their ease of installation and environmental sustainability, make them a good choice for ensuring the longevity and reliability of plumbing systems.

-

Feedback

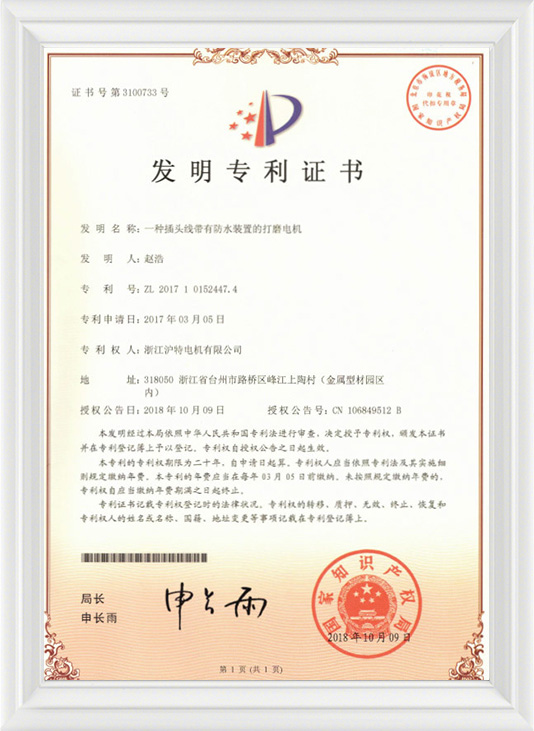

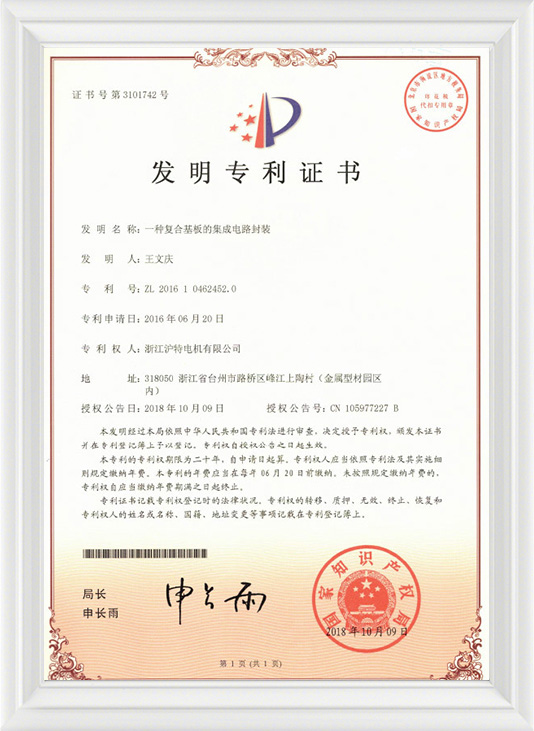

The company has the most advanced automated CNC production equipment and a first-class team of technical engineers in the industry. The company has passed ISO900 international quality system certification, "CCC" certification, "CQC" certification, "CE" certification, "National Industrial Product Production License", "Conformity Certificate of explosion-proof", and "Safety certification of approval for mining products", and has multiple independently developed patent products. Our main products include YE3, YE4, YE5, YD2, YVF2, YVP2, YS, YEB2, YDEJ2, YL, YQB, YB3, YBX3, YBX, YBX5, YBK3, YBBP, and other series of three-phase asynchronous motors have the characteristics of high efficiency, energy saving, high starting torque, low noise, reasonable structure, reliable operation, elegant appearance, and convenient installation and use.

-

As global industries continue to pursue stable operation and smarter energy use, electric motors are receiving renewed attention across manufacturing, infrastru...

READ MORE -

Across global manufacturing communities, conversations around motor selection are becoming more strategic than ever. Engineers, plant managers, and procurement ...

READ MORE -

In global industrial discussions, energy efficiency is no longer viewed as a technical bonus—it has become a core purchasing factor. Across LinkedIn, industry f...

READ MORE -

As global manufacturing continues to adapt to rising energy awareness and supply chain optimization, motor selection has become a strategic decision rather than...

READ MORE -

In today’s rapidly evolving industrial landscape, manufacturers and system integrators are actively seeking motor solutions that combine energy efficiency with ...

READ MORE -

As industries worldwide strive for higher efficiency and lower operating costs, the Second Class Energy Efficient Motor has emerged as a key solution for modern...

READ MORE -

In today’s industrial and commercial markets, energy efficiency and long-term reliability are key considerations for buyers. The Second Class Energy Efficient M...

READ MORE -

As regions worldwide accelerate their shift toward smarter, leaner, and more automated production ecosystems, the attention on sustainable power technologies ha...

READ MORE

English

English русский

русский Español

Español عربى

عربى