In industries where safety is important, the High Efficiency Explosion-Proof Dust-Proof Three-Phase Asynchronous Motor stands as a beacon of reliability and performance. Designed to operate in environments with the potential for explosive dust or gas mixtures, these motors are a testament to the intersection of safety, efficiency, and technological innovation.

YBX5 High Efficiency Explosion-Proof Dust-Proof Three-Phase Asynchronous Motor

-

Description

1. Enhanced Safety Features:

The primary advantage of these motors is their ability to operate safely in environments where explosive dust or gases are present. The explosion-proof design ensures that any internal sparks or heat generated by the motor cannot ignite the surrounding atmosphere, thus preventing explosions and safeguarding the workforce and equipment.2. Dust-Proof Construction:

The dust-proof construction of these motors is crucial in industries where dust is a common byproduct or contaminant. By preventing dust from entering the motor, the risk of dust accumulation, which can lead to overheating and failure, is significantly reduced. This feature also helps in maintaining the motor's efficiency and longevity.3. High Efficiency:

High efficiency is not just a selling point but a necessity in today's energy-conscious world. These motors are designed to consume less power while providing the same output as their less efficient counterparts. This results in lower energy bills and a reduced carbon footprint, aligning with both economic and environmental sustainability goals.4. Robust Construction:

The robust construction of these motors allows them to withstand the harsh conditions often found in hazardous areas. From high temperature to mechanical stress, these motors are built to last, reducing the need for frequent replacements and less downtime.5. Compliance with International Standards:

To ensure the highest level of safety, these motors are designed to comply with international standards such as ATEX (Atmosphères Explosibles) and IECEx (International Electrotechnical Commission Explosive Atmospheres). Compliance with these standards guarantees that the motors meet the strictest safety requirements globally.6. Versatility in Applications:

The versatility of these motors is another significant advantage. They can be used in a wide range of applications, from mining and petrochemical industries to food processing and pharmaceutical manufacturing. This adaptability makes them a valuable asset across various sectors.7. Low Maintenance:

Due to their dust-proof and explosion-proof design, these motors require less frequent maintenance. The reduced ingress of dust and other contaminants means that the internal components are better protected, thus a longer service life and lower maintenance costs.8. Noise Reduction:

Many high efficiency motors are also designed with noise reduction in mind. This feature is particularly beneficial in environments where noise pollution can be a concern, contributing to a safer and more comfortable working environment.9. Environmentally Friendly:

The high efficiency of these motors not only saves on energy costs but also reduces the environmental impact of operations. By consuming less power, these motors contribute to the reduction of greenhouse gas emissions, aligning with global efforts to combat climate change.In conclusion, the High Efficiency Explosion-Proof Dust-Proof Three-Phase Asynchronous Motor is a critical component in industries where safety and efficiency are important. Their ability to operate reliably in hazardous environments, combined with their high efficiency and robust construction, makes them an essential investment for any operation looking to protect its people, equipment, and bottom line.

-

Feedback

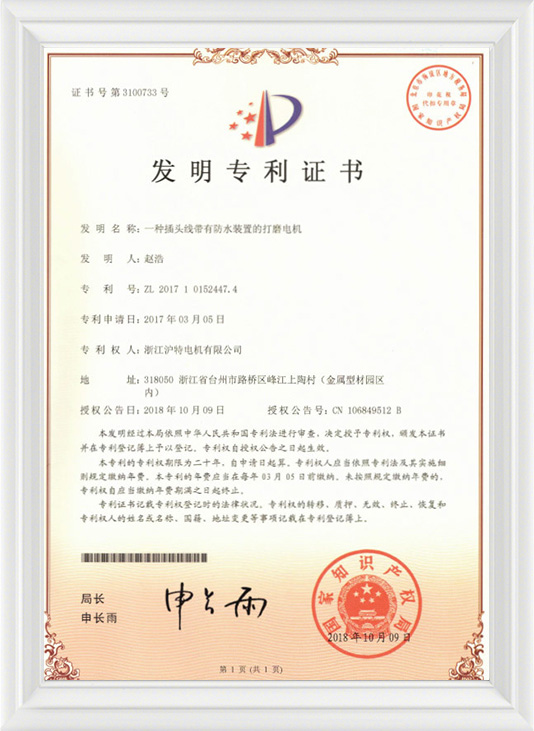

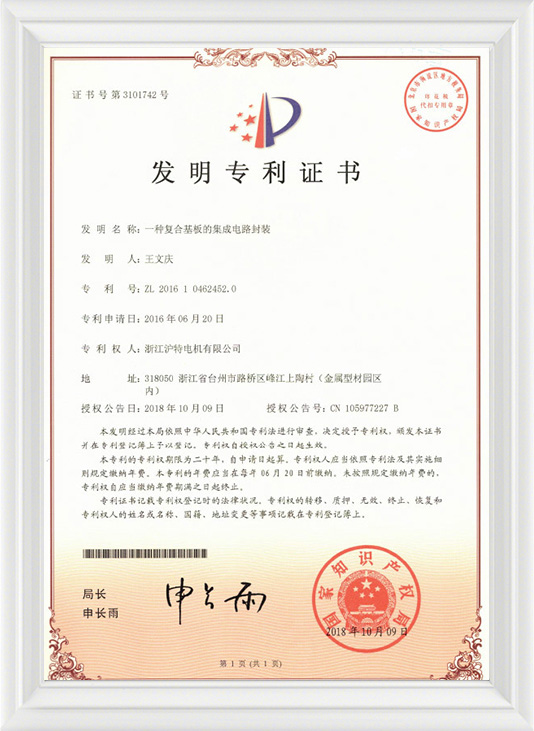

The company has the most advanced automated CNC production equipment and a first-class team of technical engineers in the industry. The company has passed ISO900 international quality system certification, "CCC" certification, "CQC" certification, "CE" certification, "National Industrial Product Production License", "Conformity Certificate of explosion-proof", and "Safety certification of approval for mining products", and has multiple independently developed patent products. Our main products include YE3, YE4, YE5, YD2, YVF2, YVP2, YS, YEB2, YDEJ2, YL, YQB, YB3, YBX3, YBX, YBX5, YBK3, YBBP, and other series of three-phase asynchronous motors have the characteristics of high efficiency, energy saving, high starting torque, low noise, reasonable structure, reliable operation, elegant appearance, and convenient installation and use.

-

As global industries continue to pursue stable operation and smarter energy use, electric motors are receiving renewed attention across manufacturing, infrastru...

READ MORE -

Across global manufacturing communities, conversations around motor selection are becoming more strategic than ever. Engineers, plant managers, and procurement ...

READ MORE -

In global industrial discussions, energy efficiency is no longer viewed as a technical bonus—it has become a core purchasing factor. Across LinkedIn, industry f...

READ MORE -

As global manufacturing continues to adapt to rising energy awareness and supply chain optimization, motor selection has become a strategic decision rather than...

READ MORE -

In today’s rapidly evolving industrial landscape, manufacturers and system integrators are actively seeking motor solutions that combine energy efficiency with ...

READ MORE -

As industries worldwide strive for higher efficiency and lower operating costs, the Second Class Energy Efficient Motor has emerged as a key solution for modern...

READ MORE -

In today’s industrial and commercial markets, energy efficiency and long-term reliability are key considerations for buyers. The Second Class Energy Efficient M...

READ MORE -

As regions worldwide accelerate their shift toward smarter, leaner, and more automated production ecosystems, the attention on sustainable power technologies ha...

READ MORE

English

English русский

русский Español

Español عربى

عربى