The Electromagnetic Braking Three-Phase Asynchronous Motor is a specialized type of motor that combines the efficiency of asynchronous operation with the safety and control of electromagnetic braking. This combination makes it a good choice for applications where precise stopping and holding are critical.

YEJ2/YDEJ2 Electromagnetic Braking Three-Phase Asynchronous Motor

-

Description

1. Enhanced Safety and Control:

The primary advantage of electromagnetic braking is the ability to stop the motor quickly and safely. This is particularly important in applications where the motor must be stopped immediately to prevent accidents or damage to equipment. The electromagnetic brake can be activated instantly, providing a high level of control over the motor's operation.2. Energy Efficiency:

Three-phase asynchronous motors are known for their energy efficiency. When combined with electromagnetic braking, this efficiency is further enhanced. The braking system can recover energy during deceleration, which can be fed back into the power grid or used to power other systems, reducing overall energy consumption.3. Reliability and Durability:

Electromagnetic brakes are known for their reliability and long service life. They require less maintenance and are less prone to wear and tear compared to mechanical braking systems. This reduces downtime and maintenance costs, making the motor a cost-effective choice for long-term use.4. Versatility in Applications:

The electromagnetic braking system can be integrated into a wide range of applications, from conveyor systems and elevators to industrial machinery and robotics. This versatility makes the motor suitable for a broad spectrum of industries, including manufacturing, logistics, and construction.5. Simplicity of Design:

The electromagnetic braking system is relatively simple compared to other braking mechanisms. This simplicity translates to fewer moving parts, which reduces the likelihood of mechanical failure and simplifies the overall design of the motor.6. Adjustable Braking Force:

One of the selling points of electromagnetic braking is the ability to adjust the braking force. This allows for precise control over the deceleration process, which can be tailored to the specific requirements of the application. This feature is particularly useful in applications where precise control over the stopping distance is necessary.7. Low Noise Operation:

Electromagnetic brakes operate with less noise, making them suitable for environments where noise pollution is a concern. This安静的 operation also contributes to a more comfortable working environment for operators.8. Environmental Compatibility:

The absence of friction in electromagnetic braking systems means there is no wear and tear associated with mechanical contact. This results in less environmental impact, as there are no brake pads or discs to replace, reducing waste and the need for disposal.9. Quick Response Time:

The electromagnetic brake can respond almost instantaneously to control signals, providing a quick and precise stopping mechanism. This is crucial in applications where rapid deceleration is required to prevent accidents or to maintain process control.10. Integration with Modern Controls:

Electromagnetic braking systems can be easily integrated with modern control systems, allowing for seamless operation with PLCs, frequency converters, and other automation equipment. This integration enables advanced control strategies, such as regenerative braking and dynamic braking, further enhancing the motor's performance and efficiency.In conclusion, the Electromagnetic Braking Three-Phase Asynchronous Motor offers a range of advantages that make it an attractive option for applications requiring precise control over motor speed and stopping. Its combination of safety, efficiency, reliability, and versatility positions it as a thus choice in the field of industrial motors.

-

Feedback

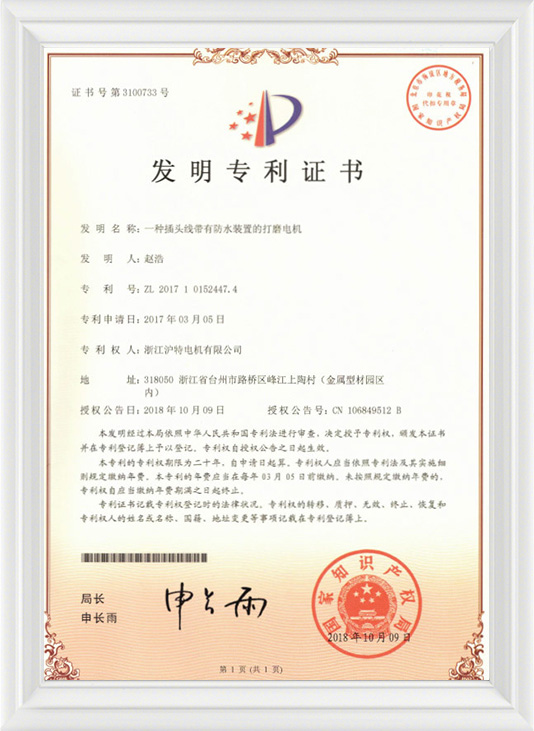

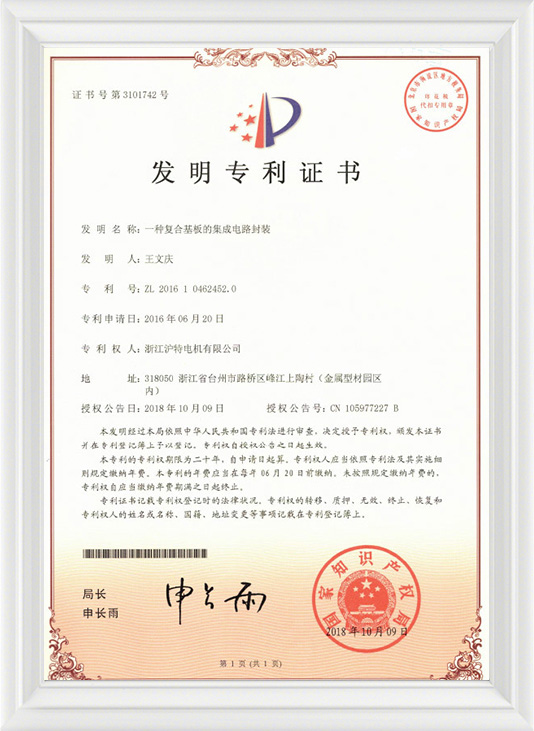

The company has the most advanced automated CNC production equipment and a first-class team of technical engineers in the industry. The company has passed ISO900 international quality system certification, "CCC" certification, "CQC" certification, "CE" certification, "National Industrial Product Production License", "Conformity Certificate of explosion-proof", and "Safety certification of approval for mining products", and has multiple independently developed patent products. Our main products include YE3, YE4, YE5, YD2, YVF2, YVP2, YS, YEB2, YDEJ2, YL, YQB, YB3, YBX3, YBX, YBX5, YBK3, YBBP, and other series of three-phase asynchronous motors have the characteristics of high efficiency, energy saving, high starting torque, low noise, reasonable structure, reliable operation, elegant appearance, and convenient installation and use.

-

As global industries continue to pursue stable operation and smarter energy use, electric motors are receiving renewed attention across manufacturing, infrastru...

READ MORE -

Across global manufacturing communities, conversations around motor selection are becoming more strategic than ever. Engineers, plant managers, and procurement ...

READ MORE -

In global industrial discussions, energy efficiency is no longer viewed as a technical bonus—it has become a core purchasing factor. Across LinkedIn, industry f...

READ MORE -

As global manufacturing continues to adapt to rising energy awareness and supply chain optimization, motor selection has become a strategic decision rather than...

READ MORE -

In today’s rapidly evolving industrial landscape, manufacturers and system integrators are actively seeking motor solutions that combine energy efficiency with ...

READ MORE -

As industries worldwide strive for higher efficiency and lower operating costs, the Second Class Energy Efficient Motor has emerged as a key solution for modern...

READ MORE -

In today’s industrial and commercial markets, energy efficiency and long-term reliability are key considerations for buyers. The Second Class Energy Efficient M...

READ MORE -

As regions worldwide accelerate their shift toward smarter, leaner, and more automated production ecosystems, the attention on sustainable power technologies ha...

READ MORE

English

English русский

русский Español

Español عربى

عربى