In today’s industrial and commercial markets, energy efficiency and long-term reliability are key considerations for buyers. The Second Class Energy E...

READ MORECATEGORIES

Sale First & Second Class Energy Efficient Motor

-

YL Dual Value Capacitor Single Phase Asynchronous Motor

-

YS Aluminum Shell Three-Phase Asynchronous Motor

-

YQB Hydraulic Oil Pump Special Three-Phase Asynchronous Motor

-

YE5 Energy-Saving Permanent Magnet Synchronous Motor

-

YBX5 High Efficiency Flameproof Permanent Magnet Synchronous Motor

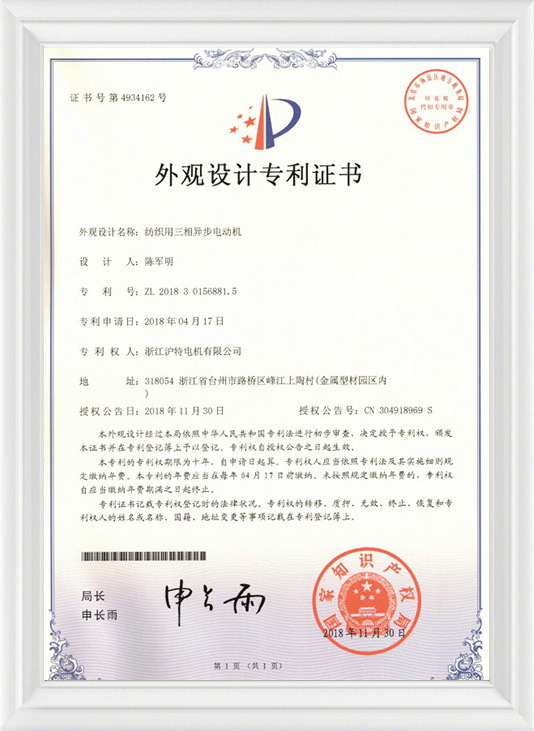

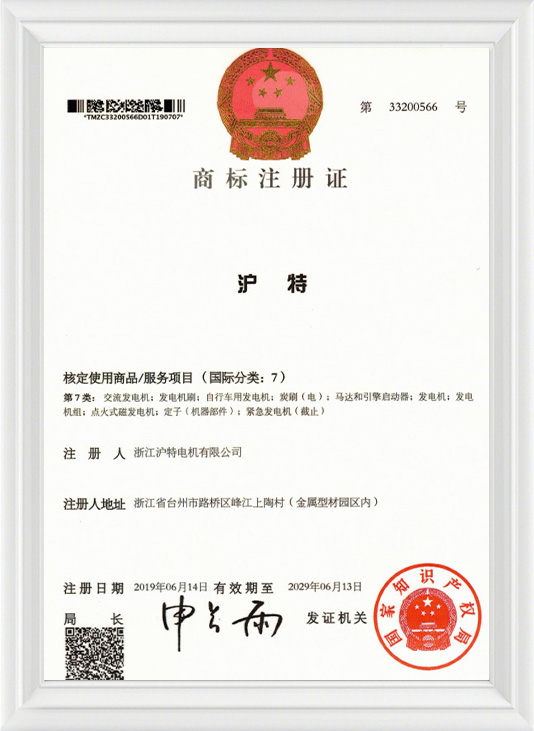

As a China Explosion Proof Motor suppliers and First Class Energy Efficient Motor factory, we are mainly engaged in wholesale Second Class Energy Efficient Motor, The company has the most advanced automated CNC production equipment and a first-class team of technical engineers in the industry. The company has passed ISO900 international quality system certification, "CCC" certification, "CQC" certification, "CE" certification, "National Industrial Product Production License", "Conformity Certificate of explosion-proof", and "Safety certification of approval for mining products", and has multiple independently developed patent products. Our main products include YE3, YE4, YE5, YD2, YVF2, YVP2, YS, YEB2, YDEJ2, YL, YQB, YB3, YBX3, YBX, YBX5, YBK3, YBBP, and other series of three-phase asynchronous motors have the characteristics of high efficiency, energy saving, high starting torque, low noise, reasonable structure, reliable operation, elegant appearance, and convenient installation and use.

The company is a member unit of the Zhejiang Electric Machinery Association and a director unit of the Taizhou Electric Motor industry. Lt has been rated as an AA level contract abiding and trustworthy unit for many years, a third-level enterprise in safety production standardization, and has been awarded honorary titles such as "National High tech Enterpri see, "Provincial Science and Technology Small and Medium-sized Enterprise", and "Rest assured Consumer Demonstration Unit".

-

-

As regions worldwide accelerate their shift toward smarter, leaner, and more automated production ecosystems, the attention on sustainable power techn...

READ MORE -

A major theme appearing across overseas industry blogs and social discussions involves the need for adaptable motors that reduce operational strain. M...

READ MORE -

Across the international manufacturing landscape, a noticeable wave of upgrades is unfolding as companies transition toward smarter, more efficient ma...

READ MORE

Brake Motor Industry Knowledge Extension

Explosion Proof Motor

Explosion proof motors are specially designed to operate safely in environments where flammable gases, vapors, or dust may be present. These motors feature robust enclosures that prevent sparks or hot surfaces inside the motor from igniting surrounding hazardous materials. Typically, the enclosure is tightly sealed and built to withstand internal explosions, containing any blast within the motor itself. This safety design is essential for industries such as chemical processing, mining, oil and gas, and grain handling, where volatile atmospheres are common. Additionally, explosion proof motors comply with strict international standards and certifications to ensure safe operation under specified conditions. Their construction often involves durable materials and precise engineering to handle harsh environments, including high humidity and corrosive elements. The use of these motors helps reduce the risk of fire or explosion, protecting both personnel and equipment while maintaining consistent motor performance.

Brake Motor

Brake motors integrate an electric motor with a braking mechanism, allowing for precise control over the start and stop functions of machinery. The built-in brake is usually electromagnetic and automatically engages when power is cut, holding the load securely in place. This feature is especially useful in applications that require immediate stopping or positioning, such as cranes, hoists, conveyors, and lifts. The brake motor not only improves safety but also enhances operational efficiency by reducing wear on mechanical brakes and enabling smoother machine control. These motors are available in various sizes and power ratings to suit different load requirements. Their construction allows for easy maintenance, and the brake system can be adjusted or replaced as needed to accommodate different operational demands. The brake motor’s ability to control load movement with precision makes it a valuable component in many industrial and commercial applications.

First Class Energy Efficient motor

First class energy efficient motors are designed to deliver reliable performance while consuming less power and losing less heat. They adhere to stringent energy efficiency standards that encourage manufacturers to optimize motor design, including improvements in winding techniques, magnetic materials, and overall motor construction. These motors reduce electricity costs and contribute to environmental sustainability by lowering energy waste. In many regions, they meet or exceed regulatory requirements, making them suitable for industries focused on reducing operational expenses and carbon footprints. First class energy efficient motors are widely used in pumps, fans, compressors, and other equipment where continuous operation demands energy savings. Their design also tends to improve motor lifespan by reducing thermal stress and mechanical wear. While initially they may have a higher purchase price compared to standard motors, the energy savings over time typically justify the investment through reduced operating costs.

Second Class Energy Efficient Motor

Second class energy efficient motors provide a balance between performance and cost, offering improved efficiency compared to standard models but with slightly relaxed design criteria relative to first class motors. These motors are manufactured to meet specific energy-saving regulations that support gradual improvements in industrial energy use. They are often selected for applications where cost sensitivity is a priority, but some level of efficiency enhancement is still desired. Second class energy efficient motors help reduce energy consumption and greenhouse gas emissions while maintaining reliable operation in common industrial settings. They are suitable for use in fans, blowers, small pumps, and general machinery. By incorporating quality materials and efficient design features, these motors achieve better efficiency than older or basic motors, contributing to moderate energy savings and reduced environmental impact without a significant increase in upfront costs.

Frequency Conversion Motor

Frequency conversion motors are designed to work with variable frequency drives (VFDs) that adjust the motor speed by changing the frequency of the supplied electrical power. This capability allows for precise control over motor speed and torque, enabling machines to operate more efficiently and adapt to varying load conditions. Frequency conversion motors are especially useful in applications where processes require variable speeds, such as in HVAC systems, conveyors, pumps, and compressors. By matching motor speed to actual demand, these systems reduce energy waste and improve process control. The motors are built to handle frequent speed changes and often include enhanced insulation and cooling to manage thermal effects from variable operation. Using frequency conversion motors can extend equipment life by reducing mechanical stress and wear while also lowering operating costs. They contribute to flexible and energy-conscious industrial solutions by optimizing motor performance for changing production needs.

English

English русский

русский Español

Español عربى

عربى