Frequency Conversion Motors See Increased Demand in Industrial Automation Projects

The rise of industrial automation has brought renewed focus to energy-efficient and adaptable motor solutions. Among the technologies gaining attention, the Frequency Conversion Motor has emerged as a key component in many upgraded manufacturing systems. As factories move toward digitized and streamlined operations, this type of motor offers flexible speed control and improved power utilization, which are particularly valuable in dynamic production environments.

A Frequency Conversion Motor adjusts its speed by changing the frequency of the electrical power supplied to it. This function allows machinery to run at variable speeds depending on load requirements, resulting in better energy use. When integrated into automated systems, it enhances responsiveness and reduces energy waste during periods of lower demand. These benefits have led to broader adoption across industries including textiles, food processing, and assembly-line operations.

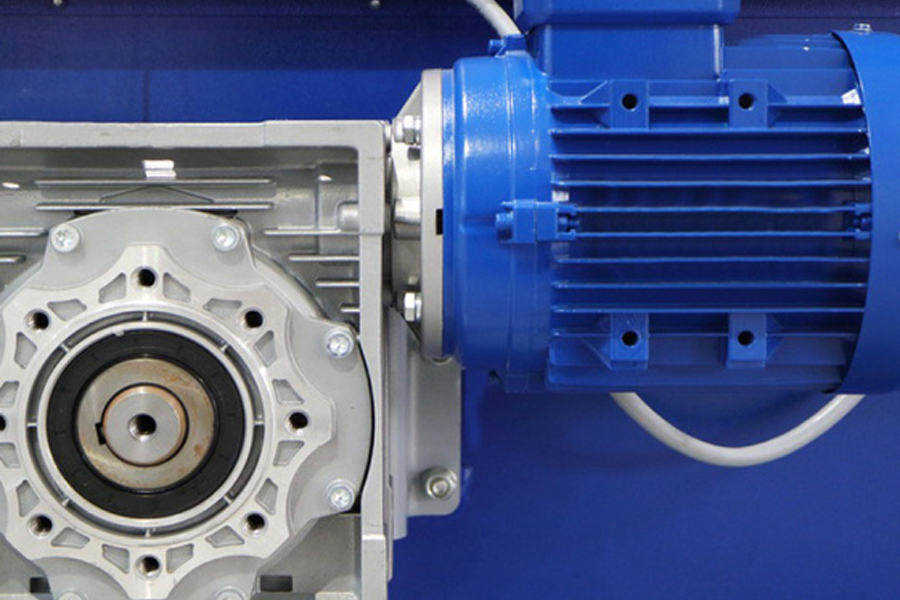

Alongside this trend, the three phase ki motor continues to play a foundational role in heavy-duty industrial settings. Known for its robust performance and consistent torque delivery, this motor type is widely applied in systems requiring reliable operation over long cycles. When paired with frequency conversion technology, a three phase ki motor can achieve greater control and adaptability, making it suitable for a wide range of equipment types.

Unlike traditional fixed-speed motors, a Frequency Conversion Motor allows equipment to operate more precisely. This is particularly useful in environments where varying workloads are common. By reducing mechanical strain and heat buildup, the motor also supports longer operational life. Additionally, its ability to handle fluctuating input conditions without performance loss contributes to more stable system behavior.

For example, in automated packaging systems, a three phase ki motor configured with frequency control can modulate its speed to match the pace of material flow. This reduces idle time and improves synchronization with upstream and downstream processes. The result is smoother operation and less energy consumed per unit of output. Engineers and facility managers are increasingly taking advantage of these capabilities as part of broader modernization strategies.

One of the key advantages of using a Frequency Conversion Motor in industrial automation is its contribution to process optimization. Machines can accelerate, decelerate, or maintain specific speeds with minimal manual intervention. In sectors where precision and timing are critical, such as electronics assembly or pharmaceutical production, this can have a noticeable impact on overall performance.

In parallel, the three phase ki motor continues to serve as the backbone of many mechanical systems. Its ability to deliver high efficiency in balanced load conditions makes it well-suited for integration into advanced control schemes. Even legacy systems can benefit from retrofitting with frequency converters, enabling older equipment to gain new capabilities without complete replacement.

As the industrial sector continues to adopt intelligent and flexible technologies, both the Frequency Conversion Motor and the three phase ki motor are becoming more visible in plant layouts and engineering plans. Companies aiming to reduce energy consumption and improve productivity are investing in these systems to meet modern operational demands.

The growing interest in industrial automation has put the spotlight on motor technologies that offer adaptability and energy efficiency. The Frequency Conversion Motor stands out for its versatility, while the three phase ki motor offers the stability and strength needed for demanding applications. Together, they support a new generation of automated systems that balance performance with sustainability, contributing to the evolving landscape of industrial design.

-

Feedback

English

English русский

русский Español

Español عربى

عربى