Aluminum Shell Motors: Aligning with Sustainability and Smart Factory Trends

Two big trends dominate today’s industrial conversations on social media and industry platforms: sustainability (meeting eco-friendly goals and reducing waste) and smart manufacturing (using data and sensors to boost efficiency). Teams aren’t just looking for motors that work—they want motors that fit into these larger goals, too. The Aluminum Shell Motor has emerged as a solution that aligns with both trends, making it a topic of discussion for forward-thinking businesses. Its aluminum casing supports sustainability efforts, while its design easily adapts to smart factory setups. This dual compatibility makes it a future-proof investment, safeguarding operations against evolving regulatory and technological demands. For teams aiming to stay ahead of industry shifts, this motor isn’t just a component—it’s a strategic choice. Below, we explore how it fits into the two most important industrial trends of today.

Why Do Sustainable Teams Prefer Aluminum Shell Motors? Recyclability Is a Game-Changer!

Sustainability is a top focus for industrial teams, who often share their eco-friendly wins on social media—from reducing waste to cutting carbon output. The Aluminum Shell Motor stands out here because aluminum is one of the most recyclable materials globally. When the motor reaches the end of its life, its casing can be melted down and repurposed into new products—no waste, no landfill. The recycling process for aluminum requires only a fraction of the energy needed for primary production, dramatically lowering its lifecycle environmental impact. Unlike motors with plastic or mixed-material casings (which are hard to recycle), this motor’s casing is a single, recyclable material that fits into circular economy goals. On industry platforms, teams often highlight their use of Aluminum Shell Motors as part of their sustainability stories, showing stakeholders they’re serious about reducing their environmental impact. For anyone looking to make tangible eco-friendly choices, this motor is an easy win.

Can Aluminum Shell Motors Help Reduce Carbon Footprints? Yes—In Simple, Impactful Ways!

Every step of a motor’s life contributes to its carbon footprint: from making the casing to transporting the motor to using it. The Aluminum Shell Motor cuts this footprint in two key ways. First, producing aluminum casings uses less energy than making steel or cast-iron ones—so the manufacturing process emits fewer greenhouse gases. Second, aluminum is lightweight, which means transporting the motors uses less fuel (whether by truck, ship, or plane). Moreover, the motor's high operational efficiency, partly due to effective heat dissipation, leads to lower energy consumption over its entire service life. These savings might seem small, but they add up for teams that buy dozens or hundreds of motors each year. On sustainability forums, industrial leaders note that switching to Aluminum Shell Motors is a simple way to lower their overall carbon output without sacrificing performance. It’s a small change that makes a real difference for eco-friendly goals.

Are Aluminum Shell Motors Compatible with Smart Factory Sensors? They’re Made for IoT Integration!

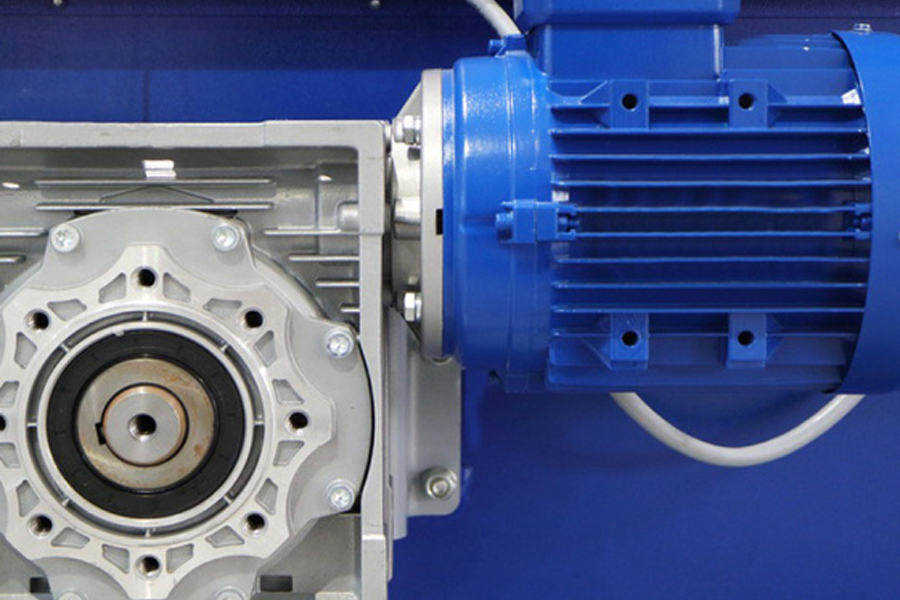

Smart factories rely on sensors to track motor performance—things like temperature, vibration, and energy use—to catch issues early and boost efficiency. The problem? Some motor casings make it hard to install these sensors: thick steel can interfere with signals, while uneven surfaces make mounting tricky. The Aluminum Shell Motor solves this with its smooth, lightweight design. Sensors attach easily to the aluminum casing without blocking signals, and the material’s thin profile lets teams place sensors where they need them to get accurate data. The casing itself can even act as an effective heat sink for integrated sensor electronics, enhancing their reliability and data accuracy. Unlike traditional motors that require extra modifications for smart tools, this motor works with IoT setups right out of the box. On smart manufacturing platforms, teams share how Aluminum Shell Motors help them integrate sensors seamlessly, making their factories more connected and efficient. For anyone moving toward smart operations, this inherent compatibility is a key advantage.

-

Feedback

English

English русский

русский Español

Español عربى

عربى